The next letter for this sign were for the word 'SHOP'. The 'S' is a length of hose, bent into an 'S' shape. A round fitting on each end looks snazzy. These were created using the dome tool To create the fittings on each end I created a longer vector, used the dome tool to create the relief and then overlaid a zero height smaller shape, By merging the longer shape to this I could effectively clip the ends square.

The 'H' is a combination of various shapes which were then MERGED HIGHEST to the base relief as a last step.

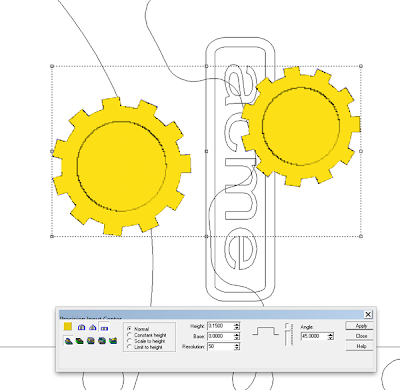

The 'O' and the 'P' were created at the same tile as the gears were similar. The 'O' gear then got a raised hub with a hole drilled into it by using the merge lowest tool and a zero height relief of that size.

The stroke of the P was created as a separate relief and then the center portion of the shape was dropped using the lettering vectors as a mask. leaving them the same height as the border.

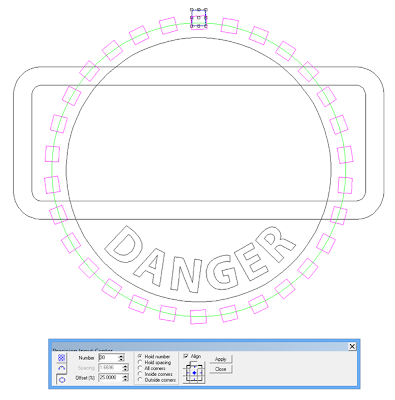

That completed the lettering and I was happy with the result. Then it was on to the border - a simple domed and raised border. I built it as a separate file as well as the rivets, then merged highest.

Give the file a try - it's great fun!

-dan