I find it a lot of fun to build rather complex files in EnRoute. They are both challenging and a great way to learn the functions of the software. Once mastered the functions of ADD, SUBTRACT, MERGE HIGHEST, MERGE LOWEST and REPLACE allows us to build some pretty interesting shapes to create just about anything we can imagine.

The second project we built at the Salt Lake City EnRoute Summit was a cute little tank. The tank was about eight inches tall. It was routed from many layers of 1" thick Precision Board.

To build the tank you have to first figure out how many layers of routed Precision Board there will be and what is on which layer. I started with the track which will be built in a front and back layer for each side of the machine. I built the vectors in EnRoute.

I started with a flat relief of the centre portion of the tread. I forgot to grab a screen capture of this step but as I recall it was 0.3" thick. The sprocket segments were next and these were added to the first relief to a depth of 0.2"

The raised boxes were next and these were created by modifying the base relief to a height of 0.2"

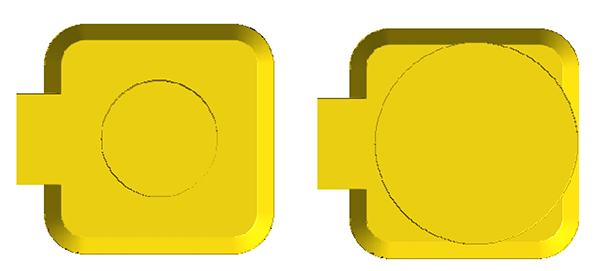

The wheels were next but because they overlapped the sprocket pieces they needed to be built as separate reliefs to a height off 0.6"

These separate wheel reliefs were then merged highest with the base relief.

The centre of the wheels was then depressed using the dome tool. I created a base of 0.1" (vertical sides) and an angle of 17 degrees. I also used the subtract from command.

I checked the front view in the non-rendered mode to make sure I had achieved what I wanted.

The wheel has were next. These were created by using the dome tool with the add to command.

Once more I checked in the front view to make sure I had what I wanted.

The lug nuts and rivets were the next order of business. I could do these all at once as they were all the same height. I used the dome tool to modify the base relief.

The cleats of the tracks were next, They were created as separate flat reliefs that were 1" tall.

Once again I checked the front view to make sure they looked as I imagined they would when I pushed the enter key on my computer.

The track cleats were spaced off of the centre portion of the assembly just a hair which meant I had to do one of two things. My first option was to create a zero height relief and then merge highest with the separate elements. This is the option I did here.

In my workshop I nudged all the separate cleats towards the centre portion and because they now overlapped the centre relief I could combine them in one click using the combine relief function in EnRoute.

To facilitate the easy mounting of the tank track to the tank I created a rectangle which I used to make a 1" high separate relief. I then copied and flipped the tank track relief and positioned the block in the center of the inside half of the track. This was then merged highest with the track.

Both the front and back tank track reliefs were duplicated as two copies of each were required. I could then tool path the reliefs and send them off the the MultiCam. As always we used 30 lb Precision Board. While the tank tracks were being routed I was busy building the files for the rest of the tank. Stay tuned for those steps...