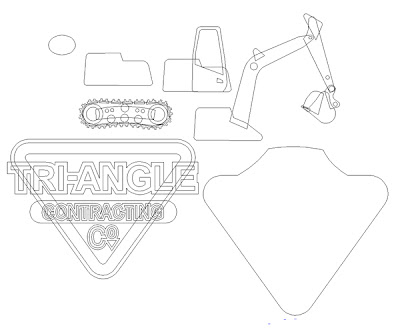

The files were routed in three stages. First I cut the reliefs using a 3/8" ball nose bit to rough out the shapes. A final pass was done with a 1/8" bit and an 80% overlap. Then I did a second cut file using a 3/8" milling tool to cut the rest of the pieces out.

The pile of pieces resembled a 3D jigsaw puzzle. It wouldn't take long to sort it out however.

First I welded up some 3" square tubing which would form the stand. the top of the 'T' would be glued into the sign making it plenty strong! I used Coastal Enterprises PB Bond-240 glue to do the task. I also used some coarse threaded screws instead of clamps to hold everything secure while things cured.

Then I started in on the pieces of the excavator. The tracks were first, then the body assembly. I hollowed out both sides of the arms to fit in a piece of 3/8" steel which I had bent to shape. Once I had two sides of the arms glued I added the other layers. It went together pretty quick.

As usual I couldn't resist mocking it up to see how it would look...

This morning everything was good and dry. I cleaned up the glue lines with my die grinder and started in on the assembly. The sides of the 'gravel pile' were whacked to shape with the die grinder. I wanted the excavator to really sit precariously on the top. To give it a cartoon flare I tipped the tracks outward at a jaunty angle, then drilled then and inserted some 1/4" steel rods. It was all glued together with some quick drying epoxy.

I cut a piece of 1" thick Precision Board on the bandsaw, then used my big belt sander to finalize the angle cuts I needed. It took me two tries to get it right. Then I glued it up. When the epoxy had set I broke out my big 5/8" drill and drilled a hole through the track frame and into the sign base. A nine inch long by 5/8" steel rod was glued in and then a similar hole was drilled into the tractor body. I'll hide the rod underneath with some small rocks as we start the sculpture. The long steel rod will make the sign much stronger than it would have been without it. High Density Urethane does not have a lot of structural strength, but it is easy to cure that woe.

Then the body was plopped on top. I won't glue it until the painting is done.

The sign faces are still being routed on the MultiCam and looking pretty good. I'll glue them on as soon as they are done. Then its on to the final detailing, primer and paint. It's going to be a wonderful addition to the shop display.

The project has gone pretty quickly so far, with about three hours of design and labor. The routing time will total about six hours once the sign faces are done. Detailing and painting will add another day of labor.

The end result will be a sign I can easily market for some pretty good dollars, with the price based on the value of the sign - not time and materials. With this type of sign my customers won't be able to go down the block to get a better price for there is only one place that makes signs like this.

I'll be posting one more set of pictures in this series before I head down to Denver for the workshop. I don't think I'll have time to paint the sign before I leave...

-dan