If you are at the show in the next few days please drop by - MultiCam, booth 712!

WELCOME!

Through extensive research and LOTS of hands-on practice I quickly found out that my MultiCam router was capable of just about anything imaginable.This journal will chronicle that journey to date and continue each week with two or three entries as I continue to explore just what is possible with this wonderful tool... -dan

Showing posts with label MultiCam display. Show all posts

Showing posts with label MultiCam display. Show all posts

Thursday, April 9, 2015

International Sign Association show

Today was the first day of the International Sign Association convention/show in Las Vegas. The display we created for MultiCam arrived safe and sound and their people had everything perfectly set up for me. It was with great pleasure I was privileged to show and talk about how we use EnRoute in conjunction with our MultiCam machine to do our dimensional work using Precision Board. It was with great delight I talked to hundreds of wonderful people, greeting old friends and new.

If you are at the show in the next few days please drop by - MultiCam, booth 712!

If you are at the show in the next few days please drop by - MultiCam, booth 712!

Friday, March 20, 2015

Packing for the ISA sign show

I'm really looking forward to attending the International Sign Association show in Las Vegas in less than two weeks. I'll be at the MultiCam booth # 712 on the showroom floor. I look forward to meeting a lot of people and sharing my passion for creating dimensional signs.

Today in preparation for the show I began packing. My personal suitcase has to wait a little while yet but it is time to get the show pieces down south so we built a giant crate for each piece. It took eighteen sheets of plywood to fabricate the sturdy crates and they weighed in at almost 2000 lbs in total when they were all loaded.

See you soon in Las Vegas!

Today in preparation for the show I began packing. My personal suitcase has to wait a little while yet but it is time to get the show pieces down south so we built a giant crate for each piece. It took eighteen sheets of plywood to fabricate the sturdy crates and they weighed in at almost 2000 lbs in total when they were all loaded.

See you soon in Las Vegas!

Thursday, March 19, 2015

MultiCam TV

The last piece to get it's final coats of paint was the TV stand and surround. Like the others it got its light and dark silver coats of paint. The flexible hoses got their bright green metallic. Once everything had dried thoroughly a glaze was liberally brushed on and then wiped off judiciously to make it look perfectly industrial.

The TV surround was carefully assembled and wired for the LED lighting in the gauges and 'liquid tube' which was clear acrylic tubing with air bubbles cast inside. After it was assembled and the base coats were dry this too received it's industrial glaze.

I had great fun with the branding, sneaking it in thirty-one times through the display.

Monday, March 16, 2015

Robot router

Each time I watch our Multicam create a 3D file it is almost like it has a mind of its own. It is pure magic to see a block of Precision Board turn into something I previously imagined. This is what inspired the MultiCam Robot Router display piece. The starting point was this sketch.

We first welded up a sturdy steel frame. The display piece has to travel thousands of miles, will be leaned on and touched by thousands of people. We first screwed 3/4" plywood to the frame and then a second show layer of half inch thick MDF. The top is 1" thick MDF. The metal frame was extended out of the side to hold up the gantry. It is almost as sturdy and heavy as a real MultiCam!

I built the piece as I do much of our work, measuring and designing by eye, as I go. I mocked it up as the pieces came off the router, sometimes going back to the drawing board to get it all right.

Once all the front pieces were on and I was happy I then cut the middle pieces to fit over the welded steel frame and then added the back pieces. I hid internal wiring and LED lights throughout to add some bling to the final piece.

With all of the routed pieces assembled it was time for some hand work, first using the die grinder to add character and some texture to the edges and faces. Screw holes were filled and the joining bits sculpted with Abracadabra sculpting epoxy. Lastly I added all of the rivets and external decorative wires.

We then painted a texture coat of Coastal Enterprises Primer to the entire piece before hand brushing on three coats of metallic silver and gray paint. Lastly the painting crew laid on a heavy coat of brown patina to add a little grime and age to this steam punk industrial piece.

The real magic happened when I hooked up the transformer and wiring. The bright LED's glowed and brought the piece to life!

Building a trade show display is all about bringing attention to our customer's product service or business. Branding on the three pieces happens an amazing thirty-one times!

Ready to speak

As I designed the MultiCam trade show display my goal was to infuse three mechanical pieces with personality. While they are largely machine made and very precise the end goal was to make them look used and full of character.

The three pieces are now complete. The last time we looked at the lectern the pieces were beginning to go together. As always the actual build stage means some changes and tweaks. I made the bottom box a little larger so it could be used for secure storage. This also added a great deal of stability to the lectern. The traditional MultiCam feet add character and branding.

When the pieces went together I decided to move the table top supports onto the gears.

We then added a dirty glaze over the entire piece to create the mechanical, industrial magic we were looking for. One more coat of bright silver paint on the lettering finished things off nicely.

The three pieces are now complete. The last time we looked at the lectern the pieces were beginning to go together. As always the actual build stage means some changes and tweaks. I made the bottom box a little larger so it could be used for secure storage. This also added a great deal of stability to the lectern. The traditional MultiCam feet add character and branding.

When the pieces went together I decided to move the table top supports onto the gears.

We first painted the lectern in pure silvers, three coats to bring out the depth of the metal flake colors. Some bright apple green hoses added a little bling and fun.

We then added a dirty glaze over the entire piece to create the mechanical, industrial magic we were looking for. One more coat of bright silver paint on the lettering finished things off nicely.

Wednesday, March 11, 2015

The awesome mesh tool

EnRoute has many cool tools that can be used individually or together with other tools to create anything I can imagine - and that's a lot. Last week I was building some faux hydraulic cylinders for a display and the mesh tool proved to be the simplest and quickest way to get exactly what I needed in a hurry.

The cylinders are a small part of the MultiCam display for their booth to be held at the International Sign Association trade show in Las Vegas next month. This is the TV stand which I will use for my presentation.

I started with hand drawn artwork as per my usual. This artwork defined the basic look of the finished piece but did not lock down every detail. We always get better ideas as we proceed.

The original thought was to fasten the vertical piece to the backdrop the client would provide but as I set about beginning the build we decided to include a horizontal base so it would stand on its own. To make it a little sturdier some angle braces on the bottom were in order but they couldn't merely look like angle braces. We decided to camouflage then as hydraulic cylinders in true steampunk style. For an extra bit of fun I added Kris Co embossed into the cylinders - a nod to my friend Kris Hanchette, president and general manager of MultiCam.

The first step was to use the rectangle to create a zero height relief.

I then selected this relief before opening the mesh creation tool. In this fashion the mesh tool is used to modify the relief rather than creating a mesh shape alone. The menu takes you through the procedure easily.

In a few clicks I had my cylinder shape. The next step was to add the flat flange which would protrude out of the bottom of the cylinder. I would build it as a separate relief.

This separate relief is then merged highest with the base relief.

Then I fitted on all of the PVC conduits with custom routed brackets. Some domed rivets were also routed and then glued onto the back board. It looks very industrial and steampunk in a hurry. The paint will add a lot in the next days.

The cylinders are a small part of the MultiCam display for their booth to be held at the International Sign Association trade show in Las Vegas next month. This is the TV stand which I will use for my presentation.

I started with hand drawn artwork as per my usual. This artwork defined the basic look of the finished piece but did not lock down every detail. We always get better ideas as we proceed.

The original thought was to fasten the vertical piece to the backdrop the client would provide but as I set about beginning the build we decided to include a horizontal base so it would stand on its own. To make it a little sturdier some angle braces on the bottom were in order but they couldn't merely look like angle braces. We decided to camouflage then as hydraulic cylinders in true steampunk style. For an extra bit of fun I added Kris Co embossed into the cylinders - a nod to my friend Kris Hanchette, president and general manager of MultiCam.

All of the necessary vectors were drawn in EnRoute with the drawing tools including the rectangle around the piece.

The first step was to use the rectangle to create a zero height relief.

In a few clicks I had my cylinder shape. The next step was to add the flat flange which would protrude out of the bottom of the cylinder. I would build it as a separate relief.

This separate relief is then merged highest with the base relief.

I now had half of a cylinder. I duplicated it and then created the lettering we would emboss into each side. I duplicated the lettering vectors before flipping one 90 degrees (so they would read the same way no matter which side you read)

I positioned these letter vectors on the cylinders.

Then I modified the reliefs by subtracting from the reliefs using the lettering as a mask.

I made two copies of each side because we needed two cylinders. then I sent the files to the MultiCam to be routed from 2" thick 30 lb Precision Board. They were fitted over the 1" pipe braces. Other smaller pieces were fit around the end flanges to build convincing attachment points in mere minutes.

Then I fitted on all of the PVC conduits with custom routed brackets. Some domed rivets were also routed and then glued onto the back board. It looks very industrial and steampunk in a hurry. The paint will add a lot in the next days.

Two of the three pieces are nearing completion. Stay tuned to see the finished results.

-dan

Tuesday, January 27, 2015

Lectern - Part four

I've long believed that if we come up with better ideas as we are building something the plan needs to be adjusted. Sometimes it means a little more time or materials but the whole idea of doing this kind of work is to do the very best we can possibly do.

After the weekend off I came back into the shop to work on the lectern. I assembled the base and set the stand back on. As I did some finishing and fitted the gears I decided they were just too far apart from the base. After looking things over I decided the gears that theoretically adjust the tilt of the table needed to be part of the brackets rather than stand alongside. The solution required parking the gears and then cutting them to fit around the brackets. A little sculpting epoxy blended the seams together nicely.

After the weekend off I came back into the shop to work on the lectern. I assembled the base and set the stand back on. As I did some finishing and fitted the gears I decided they were just too far apart from the base. After looking things over I decided the gears that theoretically adjust the tilt of the table needed to be part of the brackets rather than stand alongside. The solution required parking the gears and then cutting them to fit around the brackets. A little sculpting epoxy blended the seams together nicely.

There is still some small bits to route and assemble but it won't be long until it is time for paint.

Monday, January 26, 2015

Lectern - Part three

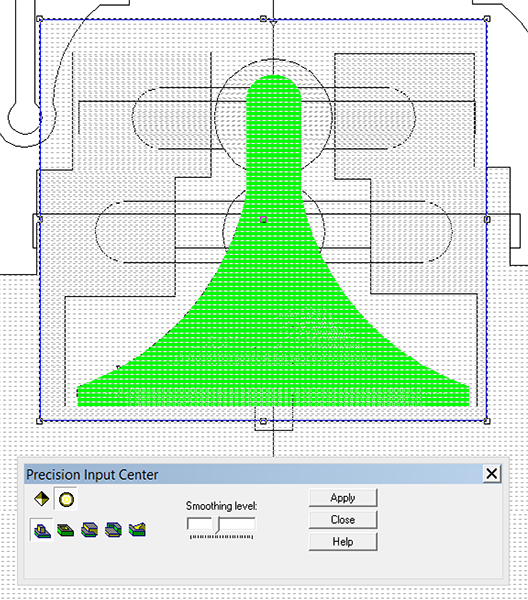

The upper portion and motor base of the lectern stand was a challenging piece to build. There were a number of ways I could have handled it but I chose to do it with a combination of domed reliefs and one mesh. The piece we were building today was shaped a bit like a funnel with a horizontal tube in the middle and a lightbulb shaped thing on the top. An axle would go through the top part for the big gears and through the horizontal tube ('motor') for the smaller gears.

The round bulb was the first and easy relief using the dome tool.

The round horizontal shaft was next. Again I used the dome tool to create this relief. I would cut the rounded ends off later.

Next up was the side down funnel shaped base. The mesh tool was used for this shape. I drew out the vectors and then used the revolve tool to create the mesh.

A square zero height relief was quickly created. Then I selected this relief and the mesh to activate the combine tool. The other oddly shaped zero height relief was also created at the same time. I would use this relief (merge lowest) to clip the ends of the hot dog shaped relief to a square shape.

I then selected this new relief and merged highest with the lightbulb and the hot dog shape.

I then created a round (flat topped) relief which would form the horizontal motor. This too would be merged highest with the rest of the relief.

Since the horizontal motor would have some square tubing inserted down the middle I created a zero height relief for that and modified the base relief by merging lowest with that square shape.

The very complex shape was then finished. Now it was simply a matter of using the slice tool to create layers which would be routed singly and then glued back together after they were cut.

The round bulb was the first and easy relief using the dome tool.

Next up was the side down funnel shaped base. The mesh tool was used for this shape. I drew out the vectors and then used the revolve tool to create the mesh.

A square zero height relief was quickly created. Then I selected this relief and the mesh to activate the combine tool. The other oddly shaped zero height relief was also created at the same time. I would use this relief (merge lowest) to clip the ends of the hot dog shaped relief to a square shape.

Once I had one relief I used the zero height odd shaped relief to clip the ends of the horizontal axle.

The very complex shape was then finished. Now it was simply a matter of using the slice tool to create layers which would be routed singly and then glued back together after they were cut.

I duplicated and flipped one set so I had both halves of the funnel shaped base. I then aligned all of the pieces to the bottom of the plate and then nested them to fit tightly together. It was time for the MultiCam to do it's job whittling them all out of a 2" thick piece of 30 lb Precision Board.

Once the router finished cutting the pieces I started the assembly process. I first used our tables to cut channels into the back to accept the welded steel frame. I could have built jigs and allowed our router to do this task but it was quicker to just do this process by hand. The steel frame was laminated into the middle of the assembly.

I sourced some adjustable feet for the display. They are slightly smaller versions of the feet on our MultiCam - just one small detail to make this thing feel authentic. Our supplier was able to deliver in only a day!

Jack, our welder had been busy cutting steel and welding up a sturdy frame while I designed the cutting files for the inner plywood skin.

As always I fit the pieces at every stage to make sure it is all looking and working correct.

Next we'll begin working on all of the bottom pieces of the base before we work our way to the top. The MultiCam Robot Man is also proceeding. I'll be posting the progress on him soon. Stay tuned...

Subscribe to:

Posts (Atom)