With Christmas mere days away now it is almost past time to get the last of the Christmas presents ready for the big day. Hailey, one of our employees reminded me today that I had promised to help her make a lighthouse name plate for someone on her Christmas list. This year I have my sister-in-law as my person to buy/make a gift for and I just hadn't got there yet. I know she loves lighthouses as well so this was a golden opportunity to kill two birds with a single stone.

I first built the vectors for the two different names. I would add the same lighthouse to both plaques as a second step. The lighthouse would be created using the rotate/extrude tool. The lighthouse profile is simply wound around an axis to create a mesh.

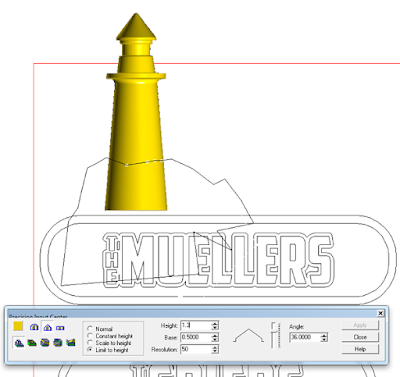

Since meshes can't be tool pathed the next step was to create a flat, zero height relief and then merge the mesh to the relief. The menu is made live by selecting both the relief and the mesh. If you look close at the menu in the picture you will see I have not yet selected MERGE HIGHEST instead of add to relief.

After you do the merging the file will look like this. Then I selected the mesh (which is still there) and deleted it.

Then I opened the create slices menu to slice the flat relief from the lighthouse as shown below.

Slicing the rleif creates new slices without destroying or modifying the original file.

The lighthouse was then resized and places where I wanted it to be in relation to the rest of the sign. To create a faceted rock I created an irregular vector shape, then created a beveled relief using the limit to height command. This slices off the top nicely at a specified height.

The last relief I made was the name tags of he sign. I've shown this process many times before. If you wish to see it select 'Name plaques' from the previous posts. Before I did this step I also created a blank copy which would be flipped to form the back side of the plaques. The next step was to merge everything together onto a single background.

The two plaques were slightly different sizes. I then arranged and tool pathed the reliefs before sending them to the MultiCam. I let the machine do its job while we went out to supper to celebrate my grand daughter Phoebe's seventh birthday.

The files had been routed from 30 lb 1.5" thick Precision Board. I blew off the dust and using the PB Bond-240 one part glue I fastened and clamped the pieces together. By morning they will be plenty ready to finish up and paint - just in time for the big day.

Stay tuned for the finished pieces tomorrow.

-dan