Yesterday was the day we would install the lighthouse portion of the sign, made from steel and concrete like many of our sculptures. The first job was to get the heavy pieces out of the shop. They were too tall to put the forklift inside the shop. We would instead drag it from the shop with our trusty little tractor. As designed there was only a bit of clearance under the door frame.

Once outside we could use the forklift to put the pieces on the trailer. I bolted custom made steel jigs to the top of each piece to facilitate to make it easy to tie the pieces in place for shipping.

Once onsite we used a big tired zoom boom to transport the pieces to the front of the property and set them into position. A crew huddled inside bolted them securely in place.

Then it was time for the last big lift - the top section. It too was lifted and carefully positioned. I was up in the basket of the snorkel lift to tighten the bolts on the upper piece.

Once everything was secure we unclipped the chains, unscrewed the eye bolt and turned in the goose weathervane.

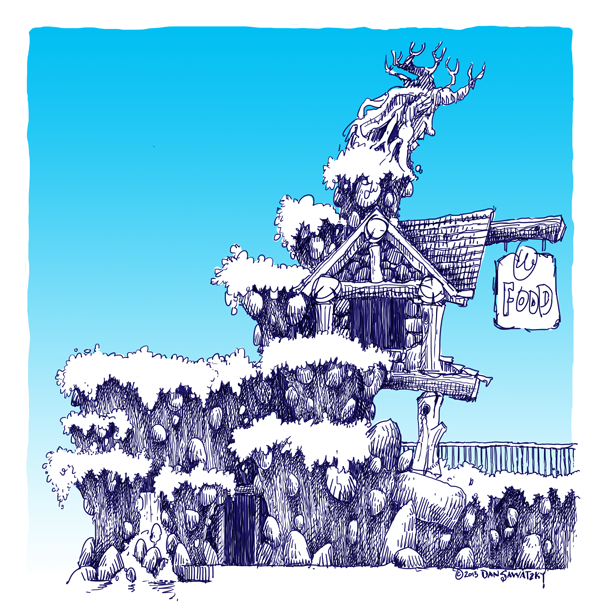

The construction site was instantly transformed into the beginnings of an exciting and colorful theme park. Late this week the sign faces will be installed, finishing off this first piece save for a little final painting and the installation of the strobe light in the cupola when the weather warms up in spring.

It's a fun process to watch unfold on a daily basis. Stay tuned for more...

-dan