I jumped into the building of my 2018 Sign Invitational piece as soon as I returned from Las Vegas nine months ago. The theme for the 2018 invitational is 'MARVELOUS MACHINE' I posted pictures of my progress perviously on the blog here. The last post was July 1. Since then we've been slammed with lots of creative projects in the shop as well as numerous business trips to Trinidad, Orlando, Salt Lake City, Atlantic City and more. That meant the piece has been mostly collecting dust since then. But with the holidays and New Year quickly approaching it was time to get back to work once more.

In the last few days I've been out in the shop after hours helping Phoebe with a school project she's working on. While I was mixing sculpting epoxy for her I also found time to work on my Sign Invitational piece once more. The piece is coming along pretty well, with the bottom two thirds almost done, with the exception of paint. I also mounted the 'human interface device' (HID) today. I used parts off an old antique typewriter I had laying around.

This coming week and over the holidays I hope to put in a little more time and hopefully will finish the sculpting. It's going to be fun!

For anyone who wishes to enter this year's fun contest drop me a line as it is time to seriously get going. dan@imaginationcorporation.com

WELCOME!

Through extensive research and LOTS of hands-on practice I quickly found out that my MultiCam router was capable of just about anything imaginable.This journal will chronicle that journey to date and continue each week with two or three entries as I continue to explore just what is possible with this wonderful tool... -dan

Sunday, December 17, 2017

Wednesday, December 13, 2017

A honey of a sign!

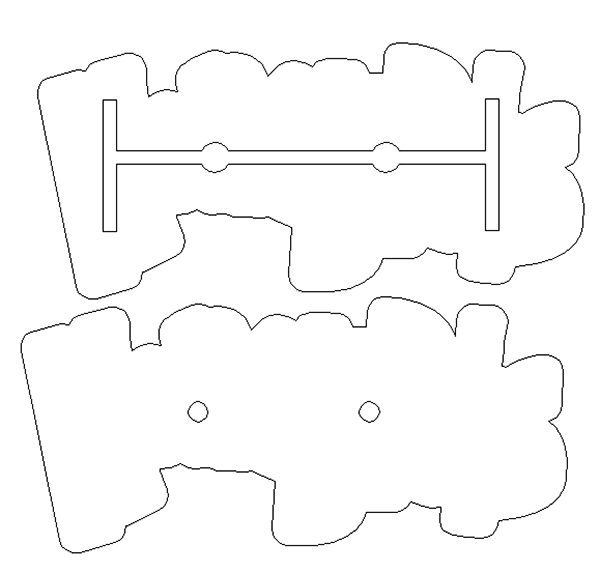

We'll be building two copies of the HoneyPot sign. One will go on the operator's booth while the second (With a sculpted bee) will be positioned at the start of the queue.

The routing file was created with three layers, rather than the two the concept art suggested. This is so the sign will better match the many others already in the park.

The sign is to be fabricated in three layers with a welded steel frame laminated into the center layer.

The routing file was created with three layers, rather than the two the concept art suggested. This is so the sign will better match the many others already in the park.

The sign is to be fabricated in three layers with a welded steel frame laminated into the center layer.

Once the file was created in EnRoute I threw a scrap piece of 30 lb Precision Board onto the router nd set the machine in motion.

It's the little things

Our MultiCam CNC plasma cutter has dramatically changed the way we fabricate our themed pieces. In the process it has ramped up the quality and durability of our work. The handy machine has also increased out productivity in a large measure.

Often it's the small hidden things that have made the most difference. A current project is a good example.

We are currently fabricating an operator's booth for a theme park ride. It is similar to many we have done previously with a few small differences. The design of the booth matches the ride. It has there legs/posts to ensure the installation is quick and easy. Three legged objects never wobble - even if the concrete pad happens to be a little uneven of off level.

Each leg needed a base plate for a couple of reasons. First the steel plate serves as a method to fasten the structure to the concrete deck. By having it extend to the outside of the sculpted concrete it protects the brittle material from chipping or cracking during the moving in the shop, transport and setting up stages. Having a CNC plasma cutter in-house means we can do custom plates in a hurry and still stay within budget and our timeline. Steel plate is relatively inexpensive. I designed the cutting file in EnRoute in a few minutes.

Cutting the there plates was even faster. Being small in size I cut them from scrap pieces which we save for this purpose. The there plates were then welded to the bottom of the legs of the operator's booth. The pencil rod will be extended down and welded to the plate. Galvanized lath will then be tied onto the pencil rod armature. A skin of fibreglass reinforced concrete will then be troweled onto that and then sculpted to look like a wood post, just like the concept drawing illustrates.

Starting a new project

Having just pushed a massive project out of the big shop doors we are doing what new always do at a time like this. First it is time for a deep clean, sweeping out the far corners of the workshop. Everything is returned to it's rightful place. If we can we take the time to go through things that don't often get done, like sorting out the piles of odd bolts and repairing cords and hoses that need attention.

It is also a time to review the job just finished. How did things go? What could we do better next time? It is all about continually raising the bar.

Then we turn our attention to the next projects. Materials are ordered and files are built. That process began today.

The first piece we are building is a windmill, but not of the ordinary kind. Our client who owns an adventure golf requested this traditional mini golf fixture and approved our version.

Since the windmill will be added to an existing golf we decided to fabricate it on a sturdy steel plate base which is cut from 3/8" thick steel. I designed the cutting vectors in EnRoute after first figuring things out with a napkin sketch.

Cutting the 3/8" thick steel plate on our MultiCam plasma cutter was a quick process. I'll do an ongoing design-build process from this point as it is the easiest way for me to create this type of complex project. I'll keep the concept firmly in my head as we work out the design from the base upwards.

It is also a time to review the job just finished. How did things go? What could we do better next time? It is all about continually raising the bar.

Then we turn our attention to the next projects. Materials are ordered and files are built. That process began today.

The first piece we are building is a windmill, but not of the ordinary kind. Our client who owns an adventure golf requested this traditional mini golf fixture and approved our version.

Since the windmill will be added to an existing golf we decided to fabricate it on a sturdy steel plate base which is cut from 3/8" thick steel. I designed the cutting vectors in EnRoute after first figuring things out with a napkin sketch.

Cutting the 3/8" thick steel plate on our MultiCam plasma cutter was a quick process. I'll do an ongoing design-build process from this point as it is the easiest way for me to create this type of complex project. I'll keep the concept firmly in my head as we work out the design from the base upwards.

Sunday, December 10, 2017

Some projects take a while

A like more than three and a half years ago I designed the primary sign for Skallywag Bay adventure Park. I designed he routing files a short time later but it would be another year before we started to build two copies of the sign. That process was chronicled here.

We routed he hulls of the ships from multiple layers of 2" thick 30 lb Precision Board.

These were glued together and hen we sculpted the details onto the two copies of the ship.

Two and a half years ago the two signs, along with hundreds of other features were carefully packed into eighteen shipping containers and then shipped through the Panama Canal to Trinidad.

Yesterday, one of these signs was the last piece to be carefully lifted into it's final home.

Wednesday, November 29, 2017

More signs at Skallywag Bay

There were a whole lot of signs which we did for Skallywag Bay in Trinidad and I'e been itching to get them installed for quite some time. During my last visit to the site we got almost all of the larger pieces placed around the site. We did it using a 60' zoom boom which is a very handy machine. I have my forklift licence for our little machine at the shop but the larger machine was a whole new experience! The key is to go slow and easy. Every move is amplified when the boom is fully extended and to reach these pieces we did just that most of the time.

The sign posts will have heavy rope work installed at a later point by someone who knows how to braid the rope and tie the proper knots.

The soil will be put into the planters around the base of the signs and the greenery will soften the look and make the signs blend better into the picture.

One Track Mine Co. - Part two

I routed three copies of the little One Track Mining Co. vehicle chassis. I'll make three different models as per the original sketches. The pieces were routed from some scraps of 1.5" 30 lb Precision Board. Since I uses a tapered 1/8" bit the track shoes routed just as I imagined, slightly thinner at the edges. I had routed the pieces with a 80% overlap which provided a smooth surface. I left a thin onion skin layer against the spoil board so the small pieces stayed put on the vacuum spoil board on the router.

Here's the same there pieces pulled apart. I simply blew the dust off the pieces with an air hose before I glued them up using a five minute epoxy and five clamps.

Once the epoxy set up I used the air powered die grinder to even out the edges. The corners and back of the hood were rounded to match the radiator cover. I'll cut and glue a little more material to the base to widen it before I start the sculpture process.

Before I started the sculpt I did up a new rendering of the wheelbarrow vehicle based on the little scale model as the engine housing/hood wasn't in my first renders. I'll do my sculpt with this new drawing as a reference. The hardest part of this build is that it will have to wait two weeks before I do it as I head out of town bright and early tomorrow morning. :) Stay tuned...

Subscribe to:

Posts (Atom)